some kindhearted members at PDVD donated to me a Luxman LV-103 and an LV105 to play around with....

they are Japanese pier units and therefore run on 100 volt mains.....

as i am perennially afraid of Murphy, i decided to convert them to 230volt mains instead...

both the LV-103 and the LV105 use the 6CG7 tube long tail pair as VAS to drive the

lateral mosfet output stage. a separate small power traffo is used to light up the filaments.....

since the 6CG7, (a 9pin analogue of the 6SN7), likes better to run on higher plate voltages,

i have decided to replace them with 6dj8 type tube, but this is another story altogether...

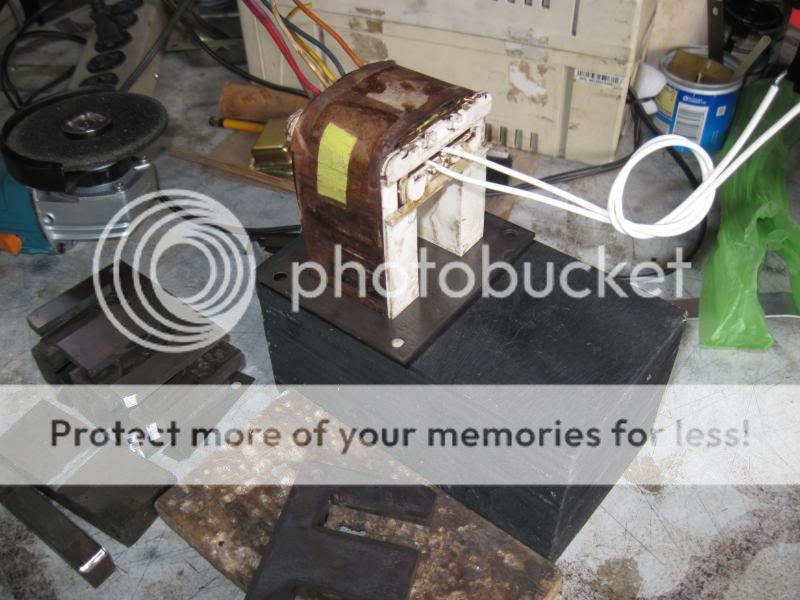

main power traffos removed:

an angle grinder was used to remove the welds on the side of the power traffos to separate the E's from the I's...

prior to grinding these 2 traffos were completely immersed in a tub full of lacquer thinner for 2 weeks.....

with the coil assembly yanked out of the core, the bobbins were pried open to separate the primary and secondary chambers.....these traffos have completely separate primary and secondary chambers so that only the primary coils is changed...the secondary coil assembly is left untouched...

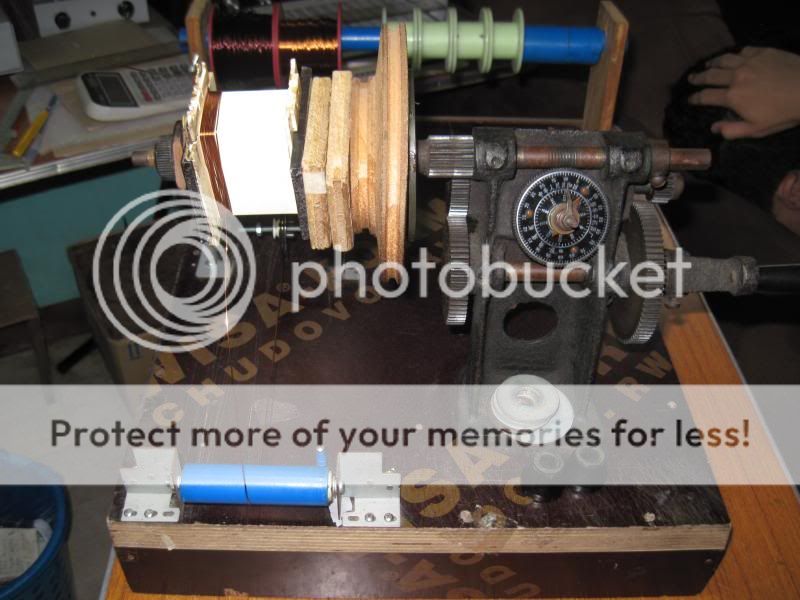

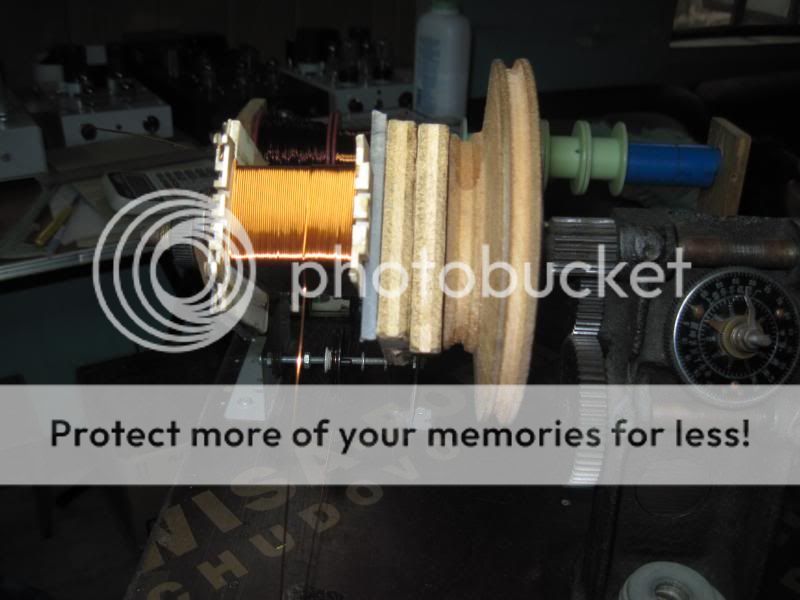

so the primary coil is put on my winder to count the number of turns which turned out to be 220 turns of #19 magnet wire, therefore at 230 volts this becomes 506 turns of #23 wire...

then comes the windup for the 230volt primary...

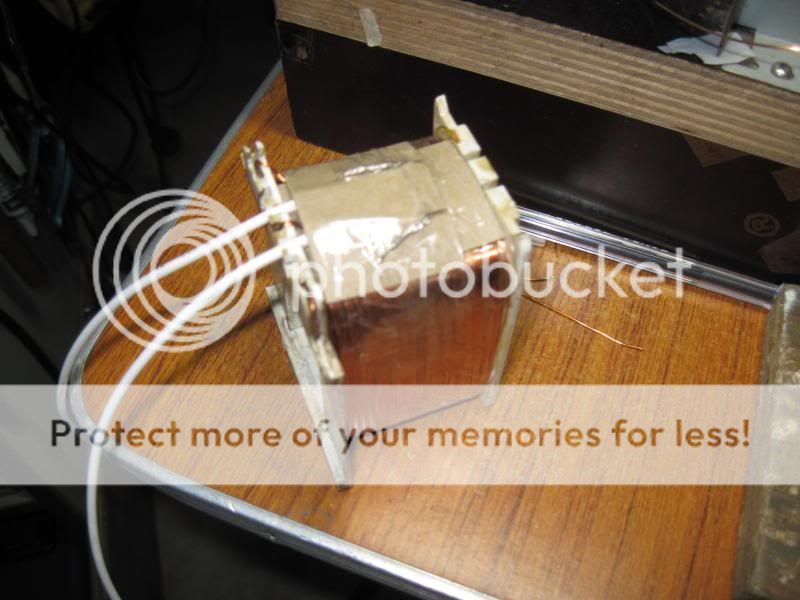

once done, installing the E and I's comes next....since i do not have access to tig welding, i decided to do the traditional interleaving, but first the weleded edge must be grinded to make it easy to separate the laminations...

the E's completed...

inserting the I's...

finally inserting the copper banding, mu-metal wrapping and mounting brackets installed completing the job..

completed traffo is immersed into a tub of clear air drying polyurethane electrical varnish..

completed traffos ready for action...

````````2nd

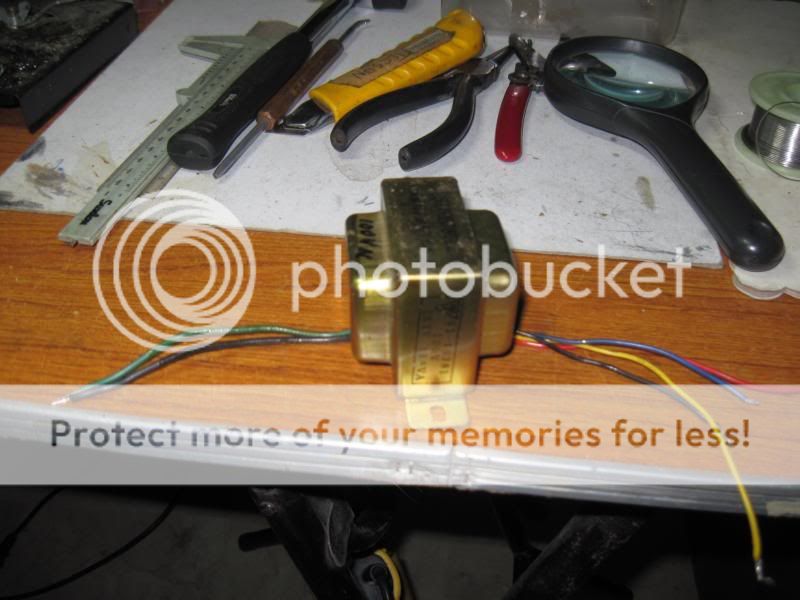

there is a 2nd smaller traffo and is used to power the tube filaments...

it is likewise converted to 230 volts..

primary turns are counted on the winder...

there were 1008 turns of #30 wire counted, to convert to 230vac,

i wind 2600 turns of #35 for primary coil..

secondary windings have two coils of 170 turns each of #25 magnet wire..

winding new primary coil...

reinserting the E-I's..

finally putting back the endbells and brackets...

completed traffo...